The Oil Mill

The company olive oil mill is situated in the middle of the olive groves in a characteristic old barn recently expanded to create spaces for oil storage, bottling, a tasting room and the store.

THE PROCESSING PHASES

Cleaning the olives: Defoliation and washing

After the harvest the olives are gathered into perforated bins. Within 8 hours, after an appropriate selection and careful controls, they are weighed and poured into a hopper from which they are channelled to the leaf and branch remover, a state-of-the-art machine made completely of stainless steel, which serves to remove any leaves, but especially any stems, twigs or larger branches that can give the oil a “tart-woody” aroma.

Then the olives reach the washing machine r that removes any impurities. These procedures guarantee greater hygiene and increased quality.

Crushing

Crushing is the first and real phase of the extraction process. Special machinery breaks down the cell walls and of the membranes allowing the cellular juices and the oil to emerge.

The olives are crushed in a hammer/knife mill, in a question of seconds; after which the olive paste obtained is poured into the malaxing tanks.

During this phase, emulsions are created between the water contained in the olives (50%) and the oil.

Malaxing

Malaxing is slow, constant mixing of the olive paste which allows small oil droplets to combine togheter in order to form bigger drops, in preparation for extraction. In this phase it is essential to maintain a low temperature and to use enclosed tanks to avoid oxidation of the paste.

Extraction

The next step consists in separating the oil from the rest of the olive components which is done by centrifugation that allows the separation of the solid parts (seed, pulp and skin) from the liquid ones (oil and water).

Extraction is done using a state-of-the-art two-and-a-half phase decanter.

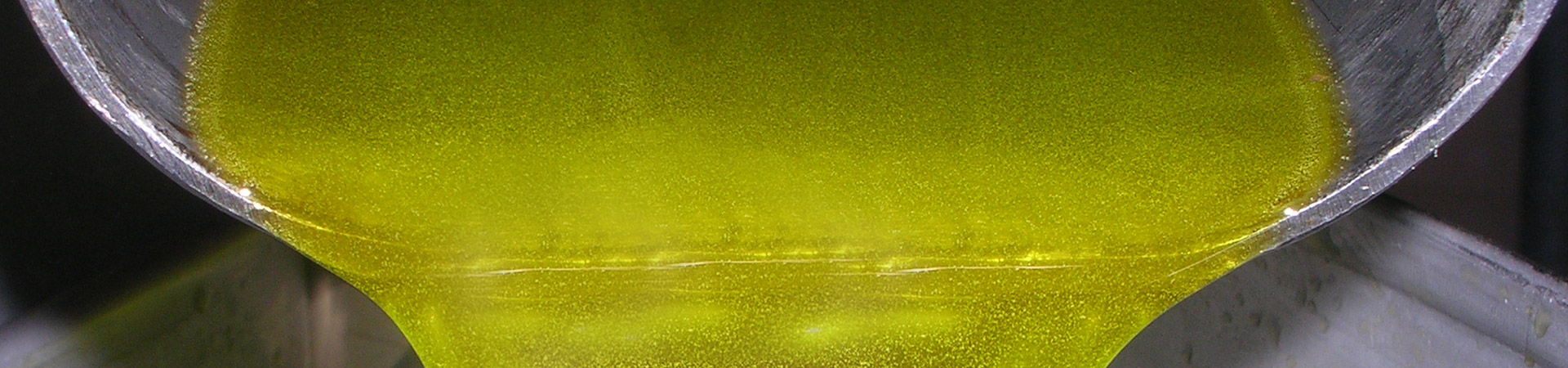

Final separation (Racking)

Extraction produces a liquid composed of oil and water, which is conducted into another vertical separator, for additional centrifugation to separate the small quantity of vegetation water still contained in the oil and vice versa.

The oil thus obtained is ready for consumption, even though it is still not perfectly transparent, but rather slightly opaque.

Oil storage

The oil produced is stored in an underground storeroom with a constant temperature of 15° C , under inert nitrogen in stainless steel tanks.

To test its quality and safety, the oil is analysed from a chemical point of view by external laboratories; and we taste it personally to check its flavour.

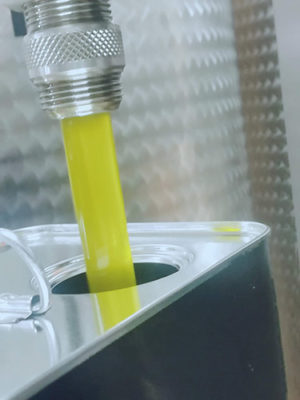

Bottling

Bottling is done in spaces adjacent to the olive-processing areas, following HACCP norms.

The bottling is done using state-of-the-art machinery; products are packaged using only dark glass bottles or food-safe tins.